A CPU Is A Thin Wafer – A Comprehensive Guide in 2024!

At the core of every modern computer is the Central Processing Unit (CPU), a critical component that executes instructions and performs calculations. While most people are familiar with CPUs as complex, powerful chips.

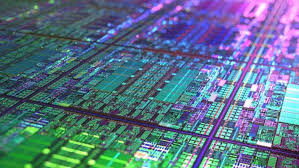

A CPU is built on a thin, flat slice of silicon called a wafer. This wafer is processed to create the tiny circuits and components needed for the CPU to perform tasks and run programs.

This article will explore the concept of a CPU being a thin wafer, breaking down its significance and the technology behind it.

The Wafer’s Role in Computer Architecture!

The wafer in computer architecture is a thin, flat piece of silicon where CPUs and other chips are made. It holds the tiny circuits that help the computer process information and run programs efficiently.

The Composition of a CPU Wafer!

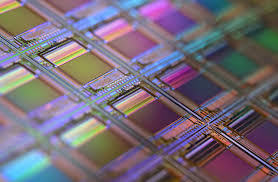

A CPU wafer is made mostly of silicon, a common material used for its good electrical properties. It’s a thin, flat disk where tiny circuits are created to build processors and other computer chips.

Manufacturing Process: From Sand to Silicon!

CPU Wafer:

A thin, flat slice of silicon is used to create multiple computer chips. It is the base on which tiny electronic circuits are built.

Manufacturing Process: From Sand to Silicon:

The process of turning sand into silicon involves melting and purifying the sand to get pure silicon, which is then formed into thin disks for making computer chips.

The Tiny Transistors on a CPU Wafer!

Tiny transistors on a CPU wafer are small electronic switches that control the flow of electricity. They are built into the wafer to perform calculations and run programs, making the CPU work effectively.

The Importance of Wafer Quality!

- Better Performance: High-quality wafers lead to more reliable and faster CPUs.

- Fewer Defects: Better wafers have fewer manufacturing defects, reducing chip failures.

- Increased Reliability: Quality wafers ensure more consistent and dependable computer operation.

- Cost Efficiency: Fewer defects mean less waste and lower production costs.

- Enhanced Durability: Good wafer quality contributes to longer-lasting and more resilient CPUs.

Wafer Fabrication Facilities!

- Specialized Plants: Facilities designed specifically for making and processing silicon wafers.

- Advanced Machinery: Uses high-tech equipment to build tiny circuits on wafers.

- Controlled Environment: Maintains clean and precise conditions to avoid defects.

- Chip Production: Converts wafers into functioning CPUs and other computer chips.

- Quality Assurance: Ensures that the wafers meet strict performance and reliability standards.

Lithography: The Key to Wafer Patterns!

Lithography:

A process used to create detailed patterns on a wafer by shining light through masks, which helps in making tiny circuit designs for computer chips.

Wafer Patterns:

The detailed designs etched onto the wafer’s surface during lithography, guide the creation of circuits and components in computer chips.

Etching and Deposition Techniques!

Etching:

A process that removes unwanted material from the wafer’s surface to create specific patterns and shapes needed for circuit design.

Deposition:

A technique used to add layers of material onto the wafer, which forms the different parts of the circuit and chip.

Advanced Wafer Manufacturing Processes!

Advanced wafer manufacturing processes use the latest technology to create more precise and efficient computer chips. These methods include improved etching, deposition, and lithography techniques to produce faster and more reliable wafers.

The Future of Wafer Technology!

The future of wafer technology includes new materials and advanced techniques to make chips even faster and more powerful. Innovations aim to improve performance, reduce costs, and enable smaller, more efficient electronic devices.

Central Processing Units (CPUs) Explained!

Central Processing Units (CPUs) are the main part of a computer that performs calculations and runs programs. They process instructions from software, making sure your computer or device works correctly and efficiently.

Types of CPUs: Desktop, Laptop, and Server!

Desktop CPU:

A powerful processor designed for home or office computers, offering high performance for tasks like gaming and productivity.

Laptop CPU:

A processor optimized for portability and energy efficiency, used in laptops to balance performance with battery life.

Server CPU:

A high-performance processor designed for servers, handling multiple tasks simultaneously and managing large amounts of data in business or data centres.

CPUs in Embedded Systems!

CPUs in embedded systems are small processors used in devices like appliances and cars. They handle specific tasks efficiently, often with low power usage, to make these devices function properly and reliably.

The Role of CPUs in AI and Machine Learning!

CPUs in AI and machine learning handle complex calculations needed for tasks like recognizing patterns and making decisions. They process large amounts of data to help computers learn and improve their performance over time.

CPUs in Gaming and Virtual Reality!

CPUs in Gaming:

Process complex calculations and instructions to ensure smooth graphics, fast response times, and high performance for an immersive gaming experience.

CPUs in Virtual Reality:

Handle intensive computations to create realistic and responsive virtual environments, ensuring smooth and immersive interactions in VR applications.

Overheating and Cooling Challenges!

Overheating:

When a CPU becomes too hot, it can reduce its performance or damage it if not managed properly.

Cooling Challenges:

The difficulty in keeping the CPU at a safe temperature using methods like fans or heat sinks to prevent overheating.

Power Consumption and Energy Efficiency!

Power consumption refers to how much electricity a CPU uses. Energy efficiency means designing CPUs to perform well while using less power, which helps save energy and reduce electricity costs.

Emerging Wafer Materials and Technologies!

- New Materials: Researchers are exploring materials like graphene and silicon-germanium to enhance wafer performance.

- Smaller Features: Advancements aim to create smaller and more precise features on wafers for better chip functionality.

- Improved Efficiency: Emerging technologies focus on reducing power consumption and increasing energy efficiency.

- Higher Speed: New materials and methods are designed to boost processing speeds and overall chip performance.

- Enhanced Durability: Innovations aim to make wafers more resistant to wear and environmental factors.

- Cost Reduction: Advances are aimed at lowering production costs while maintaining or improving performance.

- Advanced Lithography: New lithography techniques help create more detailed and accurate patterns on wafers.

- 3D Stacking: Techniques like 3D stacking are used to pack more circuits into a smaller space, improving chip capabilities.

Die Size and Wafer Utilization!

Die size refers to the size of individual chips cut from a wafer. Wafer utilization is about how effectively the wafer’s surface is used to produce these chips, aiming to maximize the number of usable chips per wafer.

Wafer Testing and Quality Control!

Wafer testing and quality control involve checking each wafer for defects and performance issues. This ensures that only high-quality wafers with properly working chips are used, preventing problems in the final products.

Wafer Packaging and Bonding!

Wafer packaging and bonding involve enclosing the processed wafer in protective materials and attaching it to a circuit board. This protects the chips and connects them to other parts of the device, ensuring they work correctly.

Wafer Recycling and Sustainability!

Wafer recycling and sustainability involve reusing materials from old wafers to reduce waste and environmental impact. This process helps conserve resources and makes the manufacturing of new wafers more eco-friendly.

The Future of CPU Wafers!

The future of CPU wafers involves using new materials and technologies to make chips faster and more efficient. Advances aim to improve performance, reduce energy use, and support the development of smaller, more powerful devices.

FAQS:

What is a CPU wafer?

A CPU wafer is a thin, flat slice of silicon used to create computer chips. It serves as the base where tiny circuits are built.

Why is wafer quality important?

High-quality wafers ensure reliable, faster CPUs and reduce defects. This leads to better performance and lower production costs.

What does the wafer manufacturing process involve?

The process involves turning sand into pure silicon, which is then sliced into thin disks for chip production. This includes melting, purifying, and shaping the silicon.

What are the challenges in wafer cooling?

Overheating can damage CPUs, so effective cooling methods like fans and heat sinks are crucial to maintain performance and prevent heat-related issues.

How do CPUs contribute to AI and machine learning?

CPUs perform complex calculations needed for AI and machine learning tasks, helping computers process data and learn from it to improve their performance.

What are the different types of CPUs?

Desktop CPUs are for high performance in home computers, laptop CPUs balance power and efficiency for portable devices, and server CPUs handle multiple tasks in business environments.

Conclusion:

A CPU starts as a thin silicon wafer, where advanced techniques create the tiny circuits essential for modern computing. The wafer’s role is crucial in computer architecture, and quality, efficiency, and new technologies continue to shape its development. Understanding CPUs and their manufacturing helps us appreciate their impact on technology and the future of computing